Dr Inġ. FRANCARL GALEA’s Electrical Interfacing Circuit is small in scale but enormous in potential. So much so that it could change the way trackers, sensors, and even pacemakers are powered.

If there is one thing we take for granted, it’s that plugging an electronic device into a power socket and switching it on works. But what happens when an electronic device is somewhere highly remote, where no sockets are available? You may think the answer is the trusty battery, but Francarl Galea’s idea may be a better solution overall.

Francarl has spent the past seven years working on his PhD in Microelectronics and Nanoelectronics. For it, he developed an Electrical Interfacing Circuit (EIC) that can store the energy it derives from energy harvesters, effectively replacing both sockets and batteries in such situations.

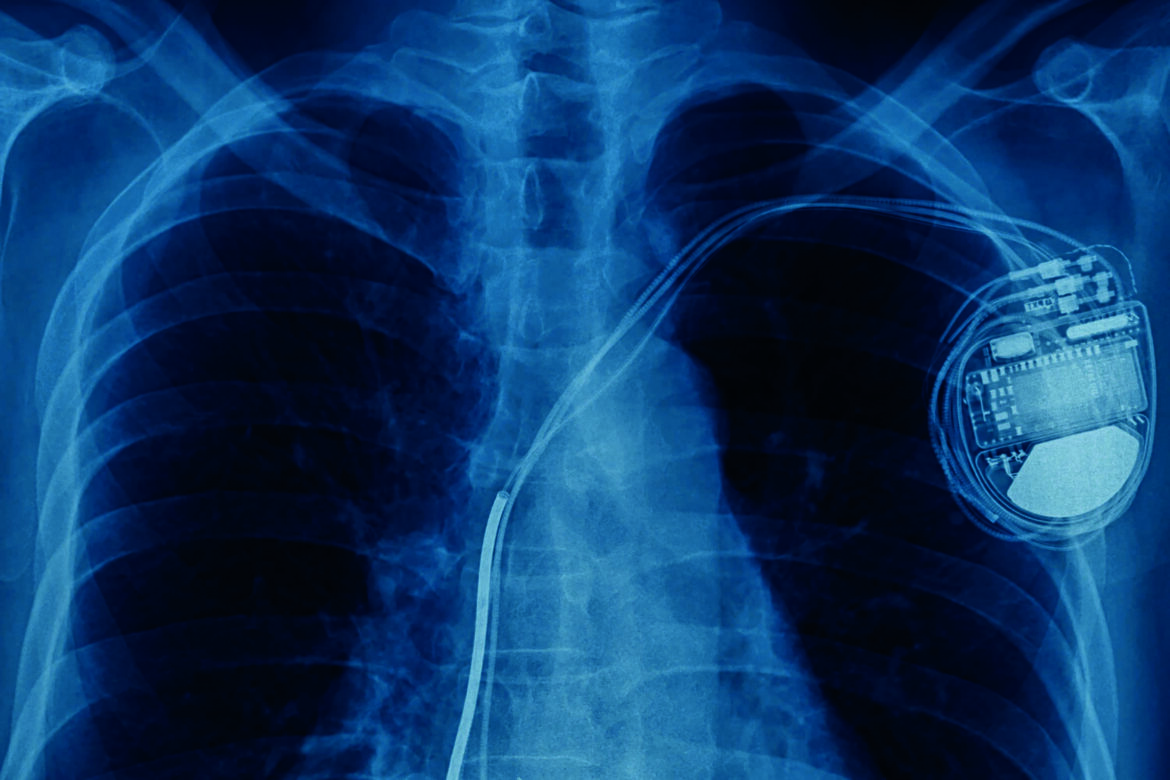

To understand this EIC, we first need to look at energy harvesters, which are devices that collect energy from a source like the Sun, the wind, or movement. These are typically used to power loads such as sensors in remote locations that alert us to natural disasters, trackers that help us study wildlife, and body implants like pacemakers, which can aid people in achieving a more regular heartbeat.

“These harvesters are indeed great,” Francarl explains, “but they have one major flaw: they are only useful when their energy source is present. So if a sensor is solar powered and the Sun has set, the object will either stop working or require a battery to function.”

To counteract this, Francarl added two significant functions to energy harvesters through his initial EIC prototype. The first was the ability to store energy, so the device can still power the load even when the source isn’t active. The second was the Maximum Power Point Tracking (MPPT) function, a technique that maximises energy extraction from the source even when conditions vary.

“All these functions were first placed together on a tiny, integrated circuit measuring no more than 1.4mm2,” he says. “The results were fantastic as we achieved up to 99% efficiency levels for the MPPT, 63% electric power conversion rates, and 95% rectification levels.”

Rectification is the conversion of alternating current (AC), where the voltage constantly changes from positive to negative and vice versa, into a direct current (DC), where the flow of electricity is constant.

“This is being done by a novel AC-DC Boost converter, which makes the EIC compatible with energy harvesters no matter what type of voltage they produce and without using any external rectification blocks.”

These functions were also included in Francarl’s second, more powerful prototype, which measures just 1.6mm2 and incorporates a regulated output voltage.

“This means that no matter how much energy the harvester collects, the amount of power supplied to the device is always controlled,” he explains.

Surprisingly, the circuitry for this EIC was implemented using analogue electronics rather than digital ones. This may seem strange today when we are used to more powerful digital electronics and microprocessors, but there was a good reason.

“The circuit only consumes two microwatts”

“If this control system had used a digital microprocessor, all the power harvested would have been used up by the circuit itself. This way, the circuit only consumes two microwatts [2/1,000,000 of a watt], which is practically nothing.”

Even better, the circuit also comes with plug-and-play functionality, allowing designers to decide what kind of energy they’d like the harvester to collect – be it solar, thermal, vibrational, or radiofrequency – and the type of voltage they’d like it to put out.

“The conversion efficiency of this circuit reached 82%, which is great considering all these components take up just 0.05mm2 on the EIC… Indeed, this is quite an advancement from what was previously available in this area, namely a regulator that prevented the energy harvester from injecting too much voltage into the device at one go.”

Francarl’s hope for this EIC is that a prospective student will now take it over and improve it. Even so, in its current state, the possibilities are countless. For example, remember the pacemakers, the sensors, and the trackers we mentioned at the start? Well, this EIC has the potential to transform the way all of them are powered, reducing their need for batteries and making them more self-sustainable. Now isn’t that a thought?