Micro Electro Mechanical Systems (MEMS) are becoming the standard in today’s devices. This is in part due to their low power consumption, but more importantly their small size allows them to take on physical properties that cannot be achieved by any other means. One application of MEMS is scanning mirrors, that are found in micro and Pico projectors and are significantly bringing down the cost of LiDAR technology, the main sensing technology in self driving cars.

Scanning Micromirrors employ one of various actuation techniques to achieve resonance. An emerging technology that is gaining popularity is actuation by piezoelectric materials. This is due to a number of factors, mainly the low driving voltage required, the linearity of the effect and its nature to be a reciprocal transducer, allowing to measure the performance of the mechanism and aid calibration.

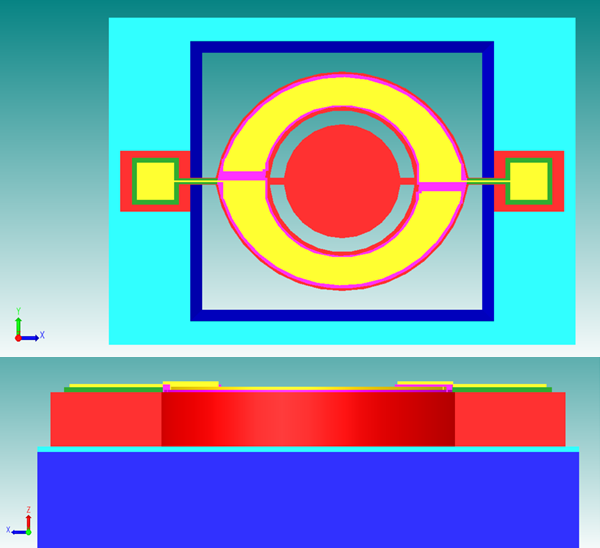

This project is centered around the research, design, and testing that goes into the design of a micromirror that is piezoelectrically actuated, with a resonant frequency of around 230KHz, the frequency required to scan or project 4K resolution horizontally at 60Hz. The micromirror was designed using Coventorware, a simulation software that can be used to design and carry out various finite-element simulations on MEMS devices.

The PIEZOMUMPs manufacturing process was used as the target process for the design of the mirror.

The mirror is made up of a silicon base, that will house the mirror and the actuator wings, that are excited electrically with opposing charges at the resonant frequency of the mirror to induce motion in one dimension. A layer of piezoelectric material is then deposited on top. An oxide layer fills in the spaces so as not to short the electrodes with the semi-conductive silicon base. Electrodes are then placed atop the structure to induce a charge in the piezoelectric material.

Substrate(Blue), Oxide(Cyan), Base(Red), Piezoelectric actuator(Magenta), Insulating Oxide(Green), Electrode(Yellow), The motion of the mirror

Student: Benjamin Barthet

Course: B.Sc. (Hons.) Computer Engineering

Supervisor: Prof. Ivan Grech