The goal of this study is to produce techniques to generate alternative user interface (UI) designs and layouts for systems with their components. This may refer to both existing UI layouts and those that are yet to be designed. This study will show that UI layouts may benefit from algorithmic reasoning. Consequently, there may be more than one UX/UI design that could fulfil the same role, whilst also increasing human-to-system interaction efficiency and additional optimal designs.

This study seeks to add to the possibilities for use of UX (user experience) and UI design and, among other benefits, reducing the time required for developing these changes – while continuing to comply with the relevant standards. [1]. It focuses specifically on hardware-oriented UIs, such as instrument panels found in manufacturing plants, transportation systems and control systems. However, the principle could also be applied to software interfaces such as tablets. This study has faced multiple challenges, given the difference between physical and virtual interfaces and the wide array of environments in which they are deployed. Therefore, the ideal focus for this study would be an instrument layout that represents the majority of properties of interfaces found in most domains, whilst also containing attributes that would be present in most systems [2]. Aircraft cockpits have been found to contain the widest range of instruments with different interfaces and functions ‒ hence being a valid test subject for this study [3]. Another challenge was on how and by what means would a layout be re-constructed. Different layouts may be specifically intended to control certain processes and there are different algorithms that could be used to carry out such control [4]. This is dependent on the nature of the problem from the point of view of the various stakeholders with respect to various factors, such as efficient space utilisation, cost effectiveness, ease of use, among others. The algorithm that would prioritise certain characteristics required thorough research and subsequent reasoning. Another challenge encountered was that many UIs, such as those found in aircraft and power stations, are multi-user interfaces. This issue falls outside the scope of this study.

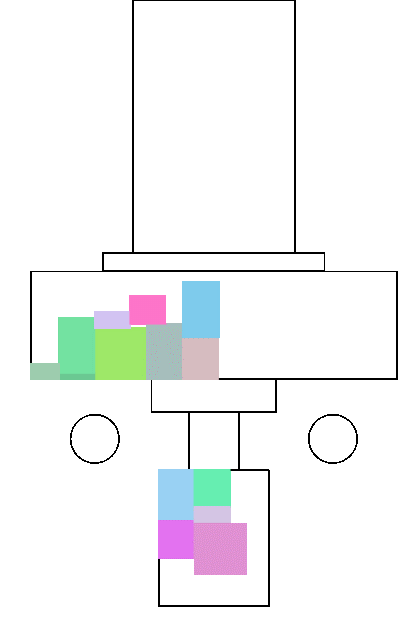

Nevertheless, the underlying proposed solution resulting from this study is a system that would take an interface as an input, and produce multiple new designs using the same components of the provided design. The solution would be produced from algorithms that could break down the interface into smaller components, which would be re-arranged as necessary, in line with specifications. Drawing from model-based design, the model could be broken down by components, to which valued attributes could be assigned individually [5]. Thus, an algorithm could utilise the newly valued components to create a new design.

This study produced three separate programs, each of which highlights a different aspect of the system. One of these focuses on displaying attributes and data of a design, and another focuses on producing new designs to be displayed in an instrument cluster. The remaining program produces new designs to be displayed and oriented in a limited area. The data has been processed through a user-submitted data file built against a template. The result of this study suggests that this proof-of-concept is valid and that a UI could be modified and improved using this methodology in order to improve the design and, consequently, the development process. This study could be further improved with more research on additional algorithms and further validation of the results of this study and integration for multi-user interfaces [6, 7].

References/Bibliography:

[1] ISO, “Systems and software engineering — systems and software quality requirements and evaluation (square) — measurement of quality in use,” International Organization for Standardization, Geneva, Switzerland, ISO ISO/IEC 25022:2016, 2016.

[2] K. H. Abbott, “Human factors engineering and flight desk design,” in Digital Avionics Handbook. CRC-Press, 1998, ch. 9.

[3] E. Suhir, “Human-in-the-loop (hitl): Probabilistic predictive modeling (ppm) of an aerospace mission/situation outcome,” Aerospace (Basel), vol. 1, 12 2014.

[4] M. Wang, C. Liu, and Y. Pan, “Computer-aided panel layout using a multicriteria heuristic algorithm,” The International Journal of Production Research, vol. 29, no. 6, pp. 1215–1233, 1991.

[5] G. Calvary and J. Coutaz, “Introduction to model-based user interfaces,” Group Note, vol. 7, p. W3C, 2014.

[6] Y. Zhang and Y. Sun, “Reuse of pilot motions for improving layout design of aircraft cockpit.” JCP, vol. 8, no. 9, pp. 2269–2276, 2013.

[7] G. Singer, “Methods for validating cockpit design the best tool for the task,” Ph.D. dissertation, Institutionen för flygteknik, 2002.

Student: Chakotay Incorvaia

Course: B.Sc. IT (Hons.) Software Development

Supervisor: Prof. Ernest Cachia