In recent years, the demand for e-commerce has grown rapidly. E-commerce businesses offering a range of products invariably require adequate storage space from where to retrieve the desired items, in order to assemble orders to be shipped to customers. Order assembly accounts for up to 65% of the cost of running a warehouse [4]. Up to 60% of the tasks of the warehouse workforce concern the retrieval of items and assembling orders, with 55% of the staff’s time being spent just moving around the warehouse [1].

This research focused on understanding the different factors affecting order assembly and the potential to automate this process. Orders are generally assembled manually by humans, which could result in inefficiencies due to physical limitations, restricted working, and the possibility of unsatisfactory work. These factors could lead to lost time, human errors, and constraints due to human limitations, such as walking, limited shift time, and overnight rates [2]. This premise served as the basis for this research, which set out to explore automated warehouse activities, specifically order retrieval and its relationship with warehouse layout.

Since the nature of a warehouse carries navigational challenges, it would be necessary to utilise path-finding heuristic algorithms, such as the vehicle routing problem (VRP), to minimise infrastructure problems. Roodbergen [3] explores warehouse-specific heuristics such as S-shape, largest-gap and aisle-by-aisle (see Figure 1). These limitations reflect the travelling salesman problem (TSP). Therefore, the present research explored the possibility of controlling a fleet of retrieval robots that move from object to object to assemble orders and return them to a central depot. The applied part of the study includes the exploration of the performance of different path-finding heuristics in different warehouse layouts. It also explores the relationship between an effective heuristic and an efficient layout for that heuristic.

The global demand for goods is constantly on the increase, and efficient warehouse management plays a major role seeking to meet this demand. With this in mind, the study analysed the relationship between frequently purchased items and warehouse operations, also taking into account costs related to travel, time and traffic.

Figure 1. Warehouse-specific heuristics, as sourced from Roodbergen [3]

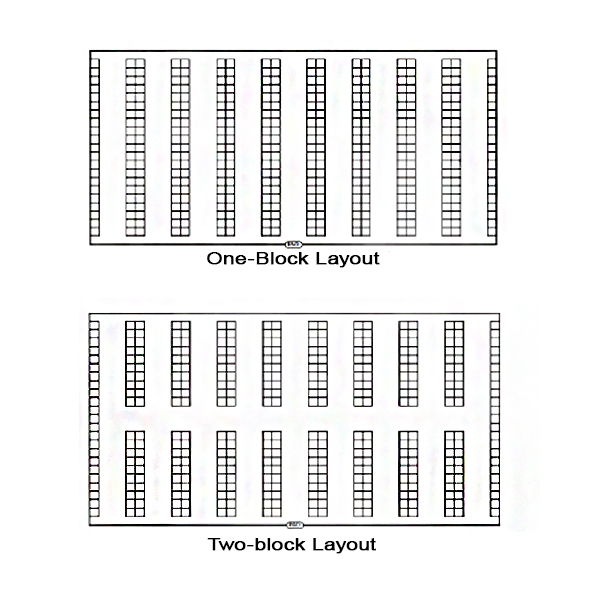

Figure 2. Warehouse layout designs excluding items, as sourced from Öztürkoğlu & Hoşer [4]

Student: Jon Jerome Micallef

Supervisor : Dr Michel Camilleri